Each time when a European trawler left her home port and headed for far-distant fishing grounds in the North Atlantic up to World War II, it was equipped with fishing gear, spare materials, and food supplies, but not least with coal and ice. The coal was the fuel for whole operation and ice was the means for preserving the catches. The volume of ice required for a three-week trip could easily amount to 80 tonnes and all ice was taken on board prior to the beginning of the trip.

From about 1910 onwards, nearly all the ice for the trawlers was manufactured by fossil fuel-powered ice works. Natural ice produced in the winter at ice ponds in the fishing ports or imported to these ports was a thing of the past and industrialized and mechanized artificial production had taken over despite the substantial energy demands of the new ice works.

Local natural ice production at places like Bremerhaven or Cuxhaven was unreliable due to often mild average winter temperatures and importing natural ice required transportation and storage. As the ice was traded in blocks it also needed to be crushed before it could be used in the fisheries. Furthermore, artificial ice was manufactured year-round in a controlled process while natural ice could only be harvested in the winter and if cut in the wrong places could be contaminated with various bacteria.

Aerial photograph of the natural ice factory in Røsneshamn, c. 1936.

Aerial photograph of the natural ice factory in Røsneshamn, c. 1936.

Photograph by Fjellanger Widerøe, c. 1936.

Courtesy of Perspektivet Museum, Norway.

Accessed via Flickr on 12 November 2020. Click here to view source.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.0 Generic License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.0 Generic License.

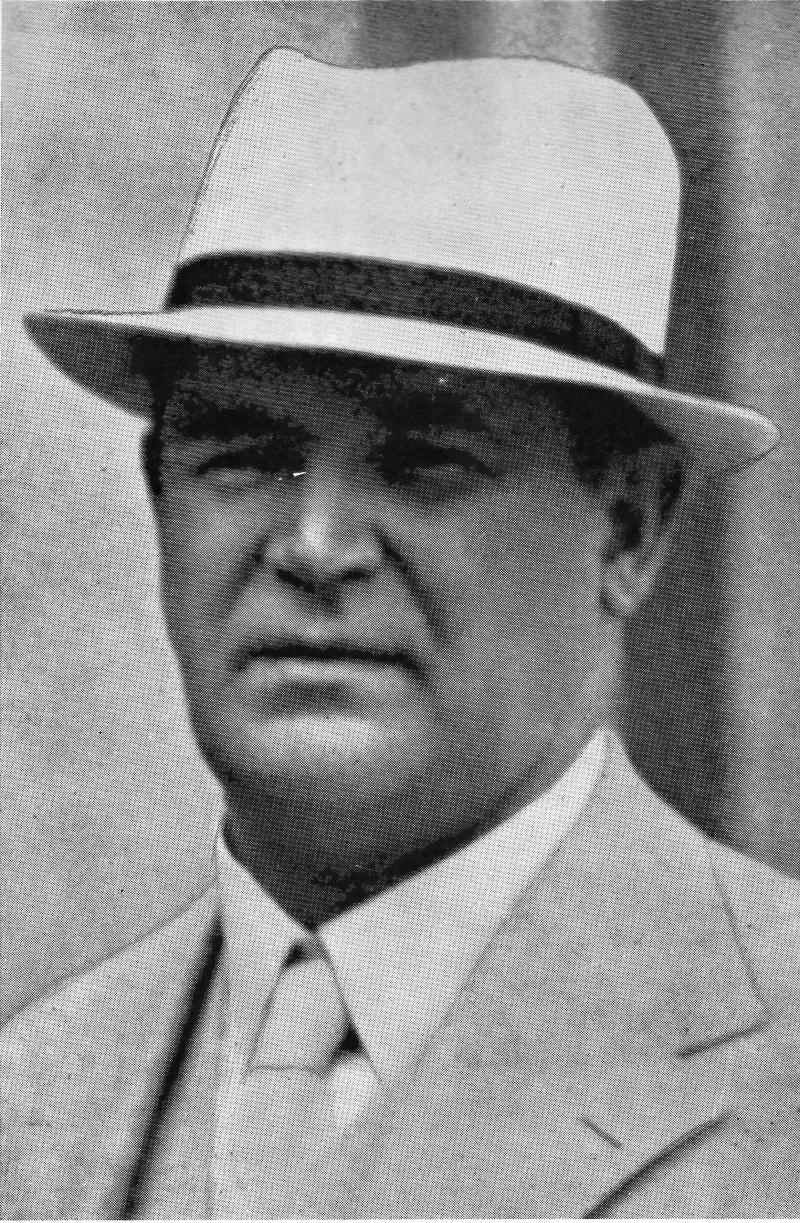

This situation changed when Harald Berg, a Norwegian entrepreneur in Tromsø, figured out that natural ice production could again provide a business opportunity and established a new large natural ice factory in 1929 a little north of Tromsø at Røsneshamn that specialized in providing ice to foreign trawlers. Contrary to the parallel experiments with deep-freezing fish, the new natural ice factory required only small upfront investments and labor was easily available for little cost due to the lack of employment opportunities in northern Norway.

Harald Berg (1881–1951)

Harald Berg (1881–1951)

Unknown photographer, n.d.

Accessed via Lokalhistoriewiki.no on 12 November 2020. Click here to view source.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License.

The Røsneshamn factory was located between a lake and an anchorage for trawlers and consisted of a huge warehouse with a capacity of more than 25,000 tonnes for the ice that was cut at the lake, a system of wooden slides between the lake, the warehouse, the pier, and an ice crushing mill at the pier, as well as barracks for the workers and a small diesel power station to provide the electricity for some conveyors and the crushing mill. Basically, it was the same design as previously used for many smaller ice factories when Norway was a major exporter of natural ice to countries like the United Kingdom, France, Belgium, and Germany prior to the invention of artificial ice production. The main differences with these earlier factories were the ice crushing mill that allowed for the direct delivery of crushed ice as needed for the preservation of catch onboard the trawlers and the factory’s location close to some of the most important fishing grounds.

The factory became a success: for example, 83 trawlers bunkered ice in Røsneshamn in the month of November 1932 alone.

While the story of the factory is interesting enough in itself, it is even more interesting to see how artificial ice producers at German fishing ports responded to the opening of the factory in Røsneshamn given its size and its potential to completely take over the ice supplies for the trawlers. Of course, the new natural ice factory was a direct competitor to their business and as the Røsneshamn factory did not need fossil fuels and large-scale upfront investments to produce ice, but simply relied on winter temperatures, production costs of ice were significantly lower than at the artificial ice works at the ports around the North Sea. In addition, there was a surplus of labor in northern Norway, so that cutting the ice at the lake could be done for very reasonable expenses.

PR material for Harald Berg’s ice operations in the Tromsø region.

PR material for Harald Berg’s ice operations in the Tromsø region.

Illustration by Anders Beer Wilse, 1939.

Accessed via the National Library of Norway on 12 November 2020. Click here to view source.

This work is licensed under a Creative Commons Public Domain Mark 1.0 License.

This work is licensed under a Creative Commons Public Domain Mark 1.0 License.

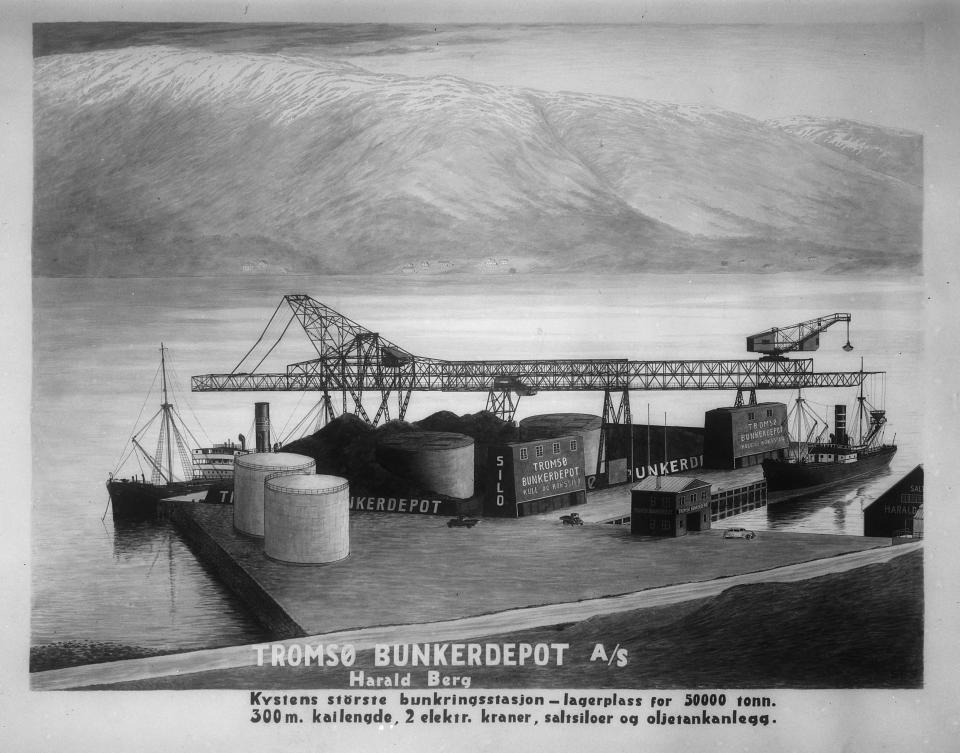

PR material for Harald Berg’s coal operations.

PR material for Harald Berg’s coal operations.

Illustration by Anders Beer Wilse, c. 1940–1949.

Accessed via the National Library of Norway on 12 November 2020. Click here to view source.

This work is licensed under a Creative Commons Public Domain Mark 1.0 License.

This work is licensed under a Creative Commons Public Domain Mark 1.0 License.

Therefore, the German ice producers employed a tactic of maligning natural ice as a potential risk for food safety, and the chief district veterinarian in Geestemünde seemed eager to help with the campaign to discredit the unexpected competitor. After going back and forth between a wide variety of administrative offices at all levels up to the Reich Ministry of the Interior, the Reichskuratorium für Technik in der Landwirtschaft, an advisory body to the Reich Ministry of Food and Agriculture, organized a research trip to northern Norway and specifically to the natural ice plants in the Tromsø region in summer 1936. The results were absolutely clear and confirmed that there was no pollution issue with the ice produced at Røsneshamn and that it could be used onboard trawlers. For the time remaining until the outbreak of World War II German trawlers operating in the Barents Sea continued using the Røsneshamn ice factory.

From an analytical environmental history perspective, the Røsneshamn ice factory is a perfect example of how a traditional production process based on a renewable resource could reemerge and compete with fossil-fuel-powered production methods. Furthermore, it shows how a technology that was considered completely outdated could compete with a highly technicized process, given that the right location was used and the size of the operation was large enough. Furthermore, it is a perfect example of how a technicized industry blamed its closer-to-nature competitor for producing products of lesser quality, polluted and unsanitary, and how even public institutions like a district veterinary clinic became complicit.

How to cite

Heidbrink, Ingo K. “The Natural Ice Factory at Røsneshamn, Norway: How to Compete with Big-Tech by Using Nature.” Environment & Society Portal, Arcadia (Autumn 2020), no. 43. Rachel Carson Center for Environment and Society. https://doi.org/10.5282/rcc/9155.

ISSN 2199-3408

Environment & Society Portal, Arcadia

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

2020 Ingo K. Heidbrink

This refers only to the text and does not include any image rights.

Please click on the images to view their individual rights status.

- Bratrein, Håvard Dahl. Karlsøy og Helgøy bygdebok. Vol. 4. Karlsøy: Karlsøy kommune, 1994.

- Dodds, Klaus. Ice: Nature and Culture. London: Reaktion Books, 2018.

- Loeser, Erwin. “Die Verwendbarkeit des norwegischen Natureises zur Frischhaltung von Seefischen.” Supplement no. 3, Zeitschrift für die gesamte Kälte-Industrie 7 (1937).

- Heidbrink, Ingo. “Deutschlands einzige Kolonie ist das Meer!” : die deutsche Hochseefischerei und die Fischereikonflikte des 20. Jahrhunderts. Hamburg: Convent, 2004.

- Peters, Dirk J. “Technische Bauten des Fischereihafens in Bremerhaven.” Deutsches Schiffahrtsarchiv 6 (1983): 243–65.

- Christensen, Pål, Atle Døssland, Åsa Elstad, Bjørn-Petter Finstad, Edgar Hovland, Nils Kolle, Arnljot Løseth, and Alf Ragnar Nielssen. Norges fiskeri- og kysthistorie. Bergen: Fagbokforlaget, 2014.

- Norseng, Per G., and Norsk Maritimt Museum. Mennesket og havet 2020. Arbok for Norsk Maritimt Museum. Trondheim: Museumsforlaget AS, 2020.